North Caporo

Energy generated sustainably with the natural and social environment

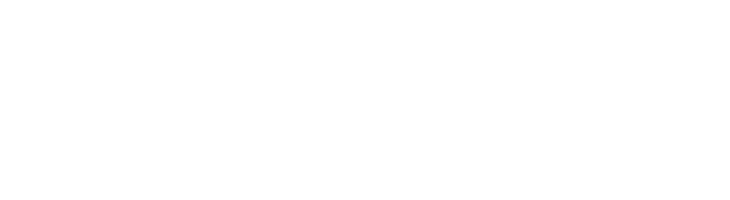

Caporo geographically

Location of the project and its areas of influence

With an area of almost 16,000 acres, Caporo is located in the municipalities of Chiriguaná and La Jagua de Ibirico (Cesar department) and has a direct socioeconomic influence on the town of Los Cerrajones (north sector), the municipality of Chiriguaná, the town of Mechoacán and the municipality of La Jagua de Ibirico.

Exploration Stage

Our North Caporo Development Area is part of the La Loma Hydrocarbons Exploration and Exploitation Contract, signed between Drummond and the National Hydrocarbons Agency (ANH) of Colombia in 2004.

Once this contract was signed, the coal-associated methane gas (CBM) exploration stage began, where the main results were:

Exploratory works for CBM areas

- Data integration: cartographic information, basin evaluation and seismic interpretation, among others.

- Data interpretation: it allowed us to build different models (stratigraphic, seismic and structural) that defined the areas of interest.

- Characterization of the deposit: the geology of both the subsoil and the surface was drilled and analyzed.

Quantification of gas contents in CBM exploration areas

- Core drilling and sampling

- Sample storage and measurement

- Measurement processing and total gas calculation

Technical evaluation of areas

- Exploration wells: electrical logs, well drilling, well completions, well stimulation

- Reservoir evaluations: reservoir pressure estimation, rock evaluation, stress characterization, permeability estimation

- Production tests: surface facilities, productivity evaluation, determination of fluid characteristics, subsurface equipment

Feasibility study

- Estimate gas quality, as well as its distribution at the regional and stratigraphic levels.

- Use the information to generate exploitation and development plans.

- Use the information to create an economic model for gas production.

- Evaluate the drilling and completion activities from the economic and technical aspects to define the best strategy.

Declaration of commerciality

Project phases

The following 6 activities divide the work in our North Caporo Development Area:

Civil works

During this phase, the area is adapted for the wells: locating and delimiting the spaces to intervene under what the environmental license authorization, improving and building access roads to the project, to new wells, as well as collection points, and, finally, building locations such as platforms for wells, water treatment facilities, among others.

Drilling

Specialized work of building a hole through the subsoil, which reaches the rock that stores the hydrocarbons. During the first 150 meters of drilling, there are usable aquifers so we protect them by the installation of casings (special high-resistance steel pipes) and with cement pumped under pressure, which keeps them isolated.

Hydraulic stimulation

Once the production wells are drilled, hydraulic stimulation is carried out through the injection of high-pressure fluids to increase hydrocarbon production. Without hydraulic stimulation, it would not be possible to produce gas in commercial quantities. This fundamental process is carried out following these 4 steps: obtaining permits, integrity tests, cannonade, and fluid pumping.

Completion

It consists of the installation of downhole and surface equipment that allow each well to start production. Includes the following activities: grinding of plugs and cleaning of the well; installation of an artificial lift system to extract formation water; construction of the well surface installations (includes gas-water separator); installation of measurement, control and telecommunications systems; and connection of well facilities to gas and water flow lines.

Production

Production is executing operation and maintenance activities of the wells, well facilities, storage facilities, water treatment and injection, flow lines (water and gas), centralized gas treatment facilities, civil and environmental works, and electrical transmission and distribution systems.

Abandonment and restoration

The regulation for well abandonment of the Ministry of Mines and Energy, states that the abandonment activities must guarantee the definitive and adequate isolation of the reservoirs that contain oil, gas or water, in such a way as to prevent possible leaks of fluids towards the surface or other reservoirs.

The operation of abandoning a well require removal of the well completion, the adequate isolation of the producing intervals, the removal of the surface facilities and the environmental recovery of the intervened area.

For its part, the revegetation of the area implies returning it to the same conditions it was in before the intervention.

Hydraulic stimulation

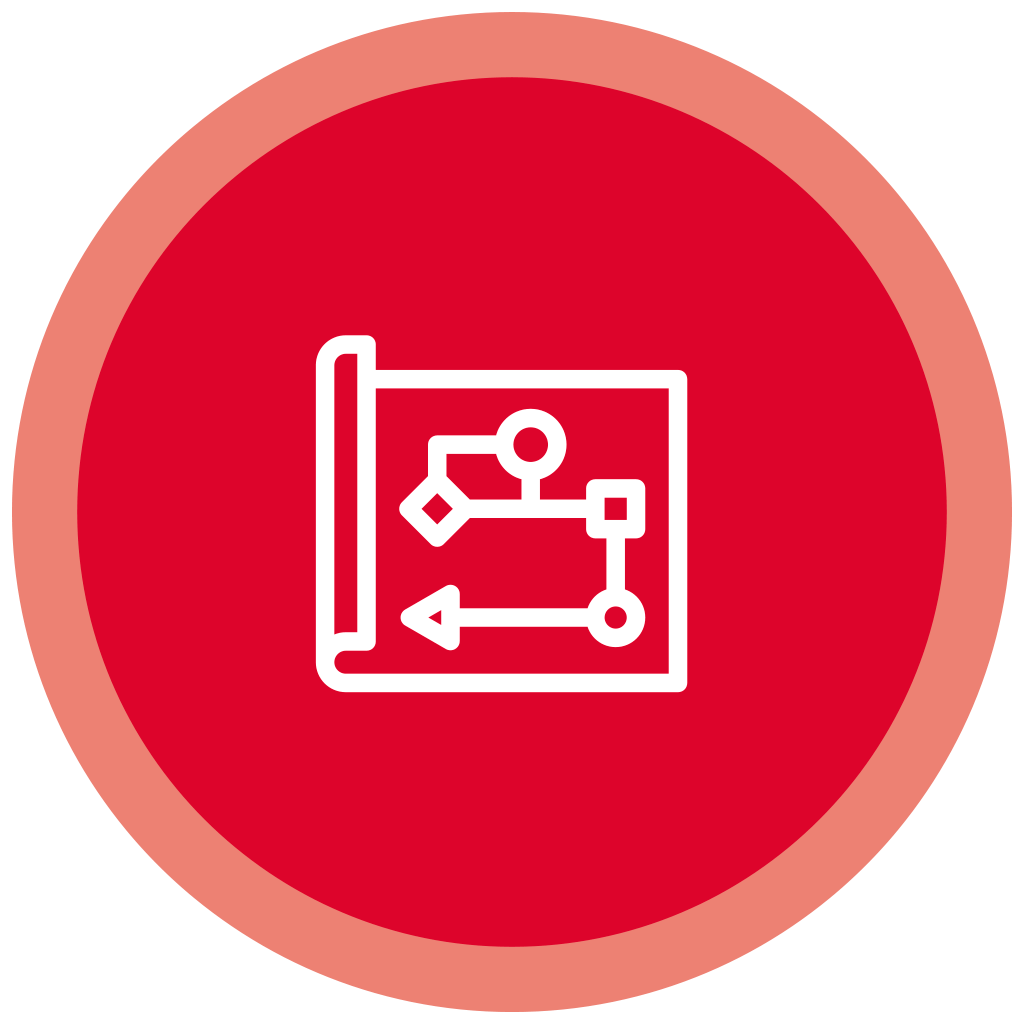

What are hydraulic stimulation fluids?

They are fluids that allow increasing the production of hydrocarbons. They generally contain water, support material (sand), and a small amount of chemical additives designed to improve fluid performance and protect coal seams.

Topics related to hydraulic stimulation fluids:

- Silica Sand CAS No 14808-60-7

- Citrus Terpenes, CAS No 68647-72-3

- Choline Chloride, CAS No 67-48-1

- Isopropyl alcohol or isopropanol, CAS No 67-63-0

- Guar Gum, CAS No. 9000-30-0

- Hydrochloric Acid, CAS No. 7647-01-0 Glutaraldehyde, CAS No. 111-30-8

- Glutaraldehyde, CAS No. 111-30-8

- Tetrasodium Ethylenediamine Teracetate, CAS No 64-02-8

- Didecyl dimethyl ammonium chloride, CAS No. 7173-51-5 Alkyl dimethyl benzyl ammonium chloride, CAS No. 68424-85-1

- Ethanol, CAS No. 64-17-5

- Acetophenone CAS. 98-86-2 98-86-2

- Tridecyl Alcohol Polyethoxylate, CAS No 68015-67-8

- Methanol, CAS No. 67-56-1

- Propargyl Alcohol, CAS No. 107-19-7

- Formaldehyde, CAS No. 50-00-0

- Heavy aromatic naphtha, CAS No 64742-94-5

- Naphthalene, CAS No. 91-20-3