Contractors and suppliers

This is how we manage our supply chain

The different suppliers and contractors supporting the operation undergo rigorous evaluation and selection processes to ensure the quality of purchasing and contracting goods and services, competitive pricing, on-time delivery, and appropriate after-sales service.

Having a supply chain that ensures the long-term operation of the Company is a key element for the sustainability of the operation of Drummond. For this reason, the different suppliers and contractors that support the operation undergo strict evaluation and selection processes.

To achieve this, Drummond. has four guidelines to ensure the right choice of suppliers and contractors:

Promote the hiring and development of local companies in the area of influence of the Port and mining operations, considering their economic and social impact.

Ensure that both suppliers and contractors follow SARLAFT standards and are not reported on the OFAC list, to comply with national and international standards. It is important to mention that Drummond conducts its SARLAFT review every three months.

Contract with solvent companies that show traceability of the origin of their capital and comply with labor, exchange and tax regulations, among others.

To contract with companies of recognized experience, in order to guarantee the supply of goods or services implementing the best national and international standards, following the best management practices and ISO 45001, ISO 14001 and other guidelines.

In order to appropriately manage the issues associated with suppliers and contractors, the Company has established controls in the various selection criteria, always with the objective of minimizing the negative impacts that may materialize due to inadequate management of a supplier or contractor; in addition, conflicts of interest may arise in the region with local suppliers and contractors, a situation to which Drummond is very attentive, and for which it socializes its strict Code of Ethics both internally and externally:

- Conflict of Interest Statement, reported by employees to the Human Resources Department (at the time of hiring, at the annual evaluation and when submitted), and by suppliers and contractors to the Company’s Supplier Control area (at the time of registration).

- Creation of the Conflict of Interest Committee, which meets periodically and not less than once a year, to assess the impacts and risks associated with suppliers and operations, as well as the implementation of measures aimed at limiting or removing these impacts.

Commitments assumed in the supply of goods and services

- Contracting through clear commercial terms regarding responsibilities, commitments and extent of services.

- Terms and conditions duly subscribed.

- Irrevocable statements.

- Reporting of the Contractors and Suppliers Manual.

- Personnel referral.

Policies and guidelines

- Reporting of the Human Rights Policy and Conflict of Interest Policy.

- Requirement of issuance, socialization and compliance with internal policies of each supplier or contractor.

Industrial safety, environmental and human rights inspections and audits

- Compliance events: periodic meetings, inspections, talks, audits and training.

Management walks

- Direct interaction sessions between the Company's management, supervision and operation of contractor companies, conducting industrial safety and environmental verifications.

Regular meetings with managers of the contractor companies

- Reporting of occupational health and safety results, both for Drummond and contractor companies' operations.

Comprehensive contractor manual

- This document informs contractors of their own and their subcontractors' main responsibilities regarding physical safety, environmental, corporate social responsibility and occupational health and safety aspects during the provision of services for Drummond.

Vendor

Risk prevention and mitigation

Drummond’s approach to risk prevention and mitigation in suppliers and contractor management aims to establish a solid supply chain; thus, the organization carries out internal audits in pursuit of this objective, which may include environmental, social and governance criteria selected in relation to the level of criticality and the invoice value of the supply and/or service rendered.

Vendor

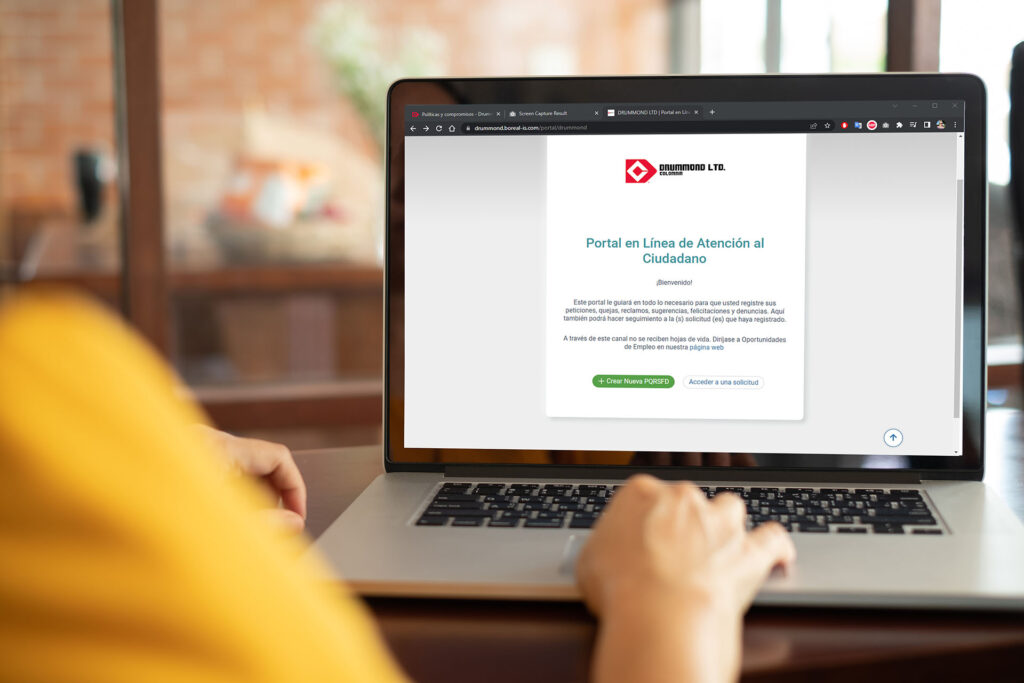

Citizen Service System (SAC)

It is a mechanism for monitoring and evaluating the performance of suppliers and contractors; this tool allows any person to file a report anonymously or directly, reporting conflicts, anomalies, failures or deviations in the Company’s Business Ethics Program, and if deemed necessary, the report can be about the subject that could affect the operation.